Test your materials in our test center

Take advantage of our offer

Experience our sorting technology live with your own material

MEYER invites interested parties to test their own materials at its test center in Michałowice, near Warsaw. Thanks to its central location in Poland, the test center is only 15 minutes away from Warsaw Chopin Airport and is easily accessible for customers from Poland and all over Europe. Our experienced specialists will carry out tests with the materials you provide. We will explain the entire optical sorting process, present the MEYER sorters, and help you find the optimal solution to control your sorting processes with maximum efficiency and increase the profitability of your company.

3 great reasons for a test at MEYER

Advantages of the feasibility study

This study shows which sorting technology can meet specific challenges. It is particularly indispensable for companies with individual or demanding sorting requirements.

Finding the right machine

During the test, we determine which sorting machine meets the required sorting criteria and has sufficient capacity to ensure long-term efficiency, safety, and profitability in your production.

Minimizing cost risk

Testing under real conditions helps prevent mispurchases that result in unnecessary costs for your company. You will know which machine you need before you buy it.

Examples of sorting solutions in agriculture, food, and recycling

Every material has its own requirements.

We help you meet them.

Every material to be sorted has its own unique properties and requirements, which necessitate an individual approach in order to achieve the best possible sorting efficiency. Our experienced experts at MEYER understand this diversity and have the expertise to recommend the most efficient solutions for your specific needs. Thanks to our in-depth understanding of different materials and state-of-the-art sorting technologies, we develop an effective and optimized sorting strategy that is perfectly tailored to the requirements of your production.

How to schedule your individual test at our center

Examples from the test center

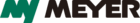

- Sorting recycled materials

For the recycling industry, we offer color, polymer, and object sorters that sort materials such as plastics (PET, HDPE, PP, PVC, etc.) based on differences in color, shape, and polymer composition. At our MEYER Test Center, we conduct live tests to evaluate the efficiency of optical sorting and optimize the solution to meet individual requirements. Our specialists analyze the material in detail and configure the sorter accordingly. The live tests allow our customers to see exactly how the sorting process works in practice, which helps them find the ideal solution for their production specifications. Our services support greater efficiency and quality in recycling processes, actively contributing to the circular economy.

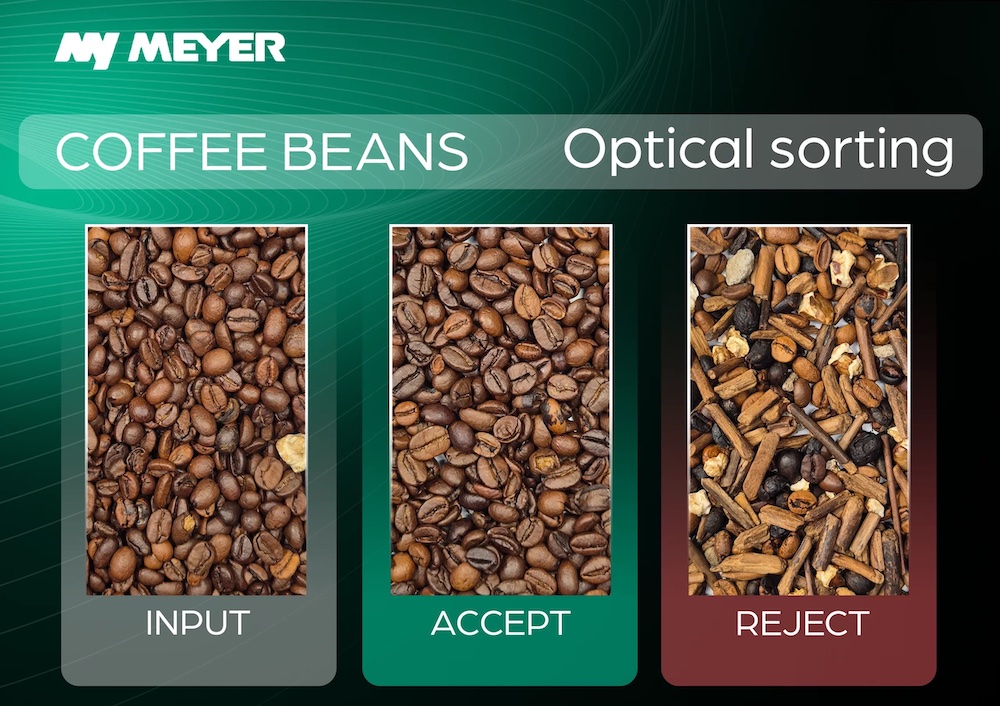

- Sorting agricultural products

For agriculture, we offer customized optical sorting solutions for seeds, grains, beans, rice, millet, and other agricultural products. Our sorters use color separation technology and InGaAs cameras to analyze the density of the grains and effectively remove damaged or inferior batches. In addition, X-ray detectors are available to eliminate foreign objects such as metal, glass, or stones and ensure the highest level of quality control. With our technologies, agricultural products are optimally prepared for further processing or sale—for maximum quality and efficiency.

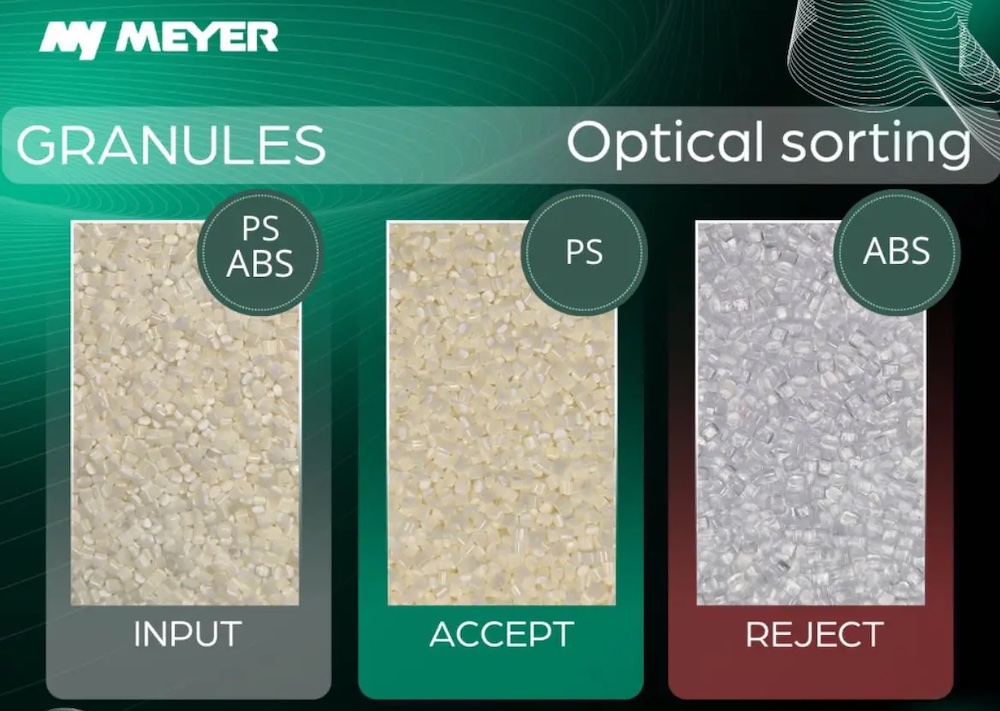

- Sorting food

Our test center offers comprehensive optical sorting solutions for the food industry. Our color and X-ray sorters enable the precise separation of materials based on color differences and the detection and removal of foreign objects such as glass, stones, or metals. Thanks to our technologies, the sorting of light materials (e.g., spices, teas) and heavy fractions (e.g., frozen vegetables or fruit) is more efficient and precise. During testing, we thoroughly analyze each material and adapt the solution to its properties to ensure the highest quality and efficiency.

Answers to your questions

Can I observe the testing process at the MEYER EUROPE test center?

Yes, the entire process begins with you sending us material samples. Our service team then develops sorting solutions. Finally, we invite you to our test center, where you can see the results of our work and how the sorting machine works in action.

How long does it take to receive the test results from the MEYER EUROPE Test Center?

The duration of the testing process depends on various factors, such as the degree of contamination of the material, the requirements for the sorting process, and the desired results. It usually takes up to two weeks to prepare the sorting solution. After that, our sales representative will either arrange a live test appointment or send you documentation with videos, pictures of the material, descriptions of the sorting stages, and material samples.

- Do I need to prepare the materials in any special way before sending them to the test center?

In order to achieve the best sorting results and obtain a solution tailored to your company’s requirements, we ask you to prepare a standard material sample that you would like to sort. Please prepare the following fractions in the quantities agreed with our sales representative:

- Mixed fraction: Standard material that you would like to sort.

- Accepted fraction: Material that represents the desired sorting result.

- Defects: Sample with contaminants that need to be removed.

Please also send a detailed description of your expectations and specify which fractions are to be separated during the sorting process. This enables the tests to be carried out precisely and ensures that your requirements are met. Thanks to a carefully conducted test process, we can select the right machines to meet your requirements in terms of performance and material purity.

Can the MEYER EUROPE test center help with the development of customized sorting solutions?

Yes, developing customized sorting solutions is a key part of our strategy at MEYER EUROPE. We firmly believe that the sale of a sorting machine should begin with tests, during which we develop the best possible solution for the customer’s specific requirements.