Technology that gets you ahead

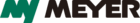

Our AI sorting systems

The optical sorting process

Optical sorting is useful for processing vegetables, fruit, grains, rice, nuts, seeds, legumes, coffee, and tea. The manufacturing and packaging process for products is complex, and few people are aware of it. For example, vegetable seasoning must not contain stones or clumps of earth, and grain must not contain glass or plastic particles. This is exactly why optical sorters are used – to protect the products. It is not only about contaminants that are visible to the naked eye, but above all about particles of various foreign substances that could be contained in these products.

- Analysis

We examine the exact current status based on the sorted material, the specific requirements, and the spatial conditions.

- Planning

Based on the findings, we draw up a precise plan for an optimal solution to the problem.

- Implementation

Our experts support you with installation in your premises and training for your staff.

Our AI-controlled sorting machines at a glance

The sorting process used by our color sorting machines is based on the usual criteria that are also applied in manual sorting. They distinguish particles according to size, shape, and color. Our X-ray sorters can also see into the material and therefore detect foreign matter in frozen goods or in closed packaging.

Sorting process

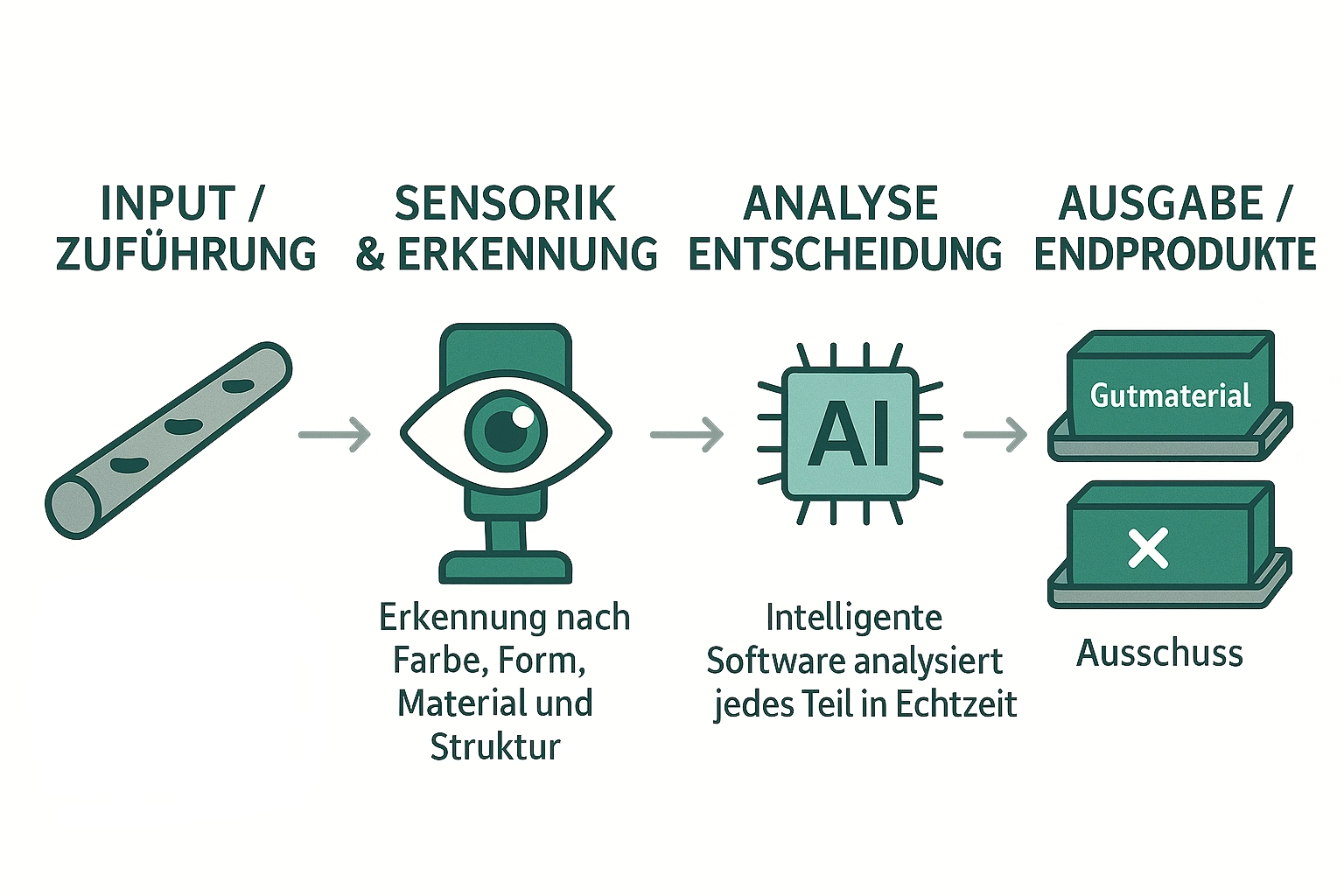

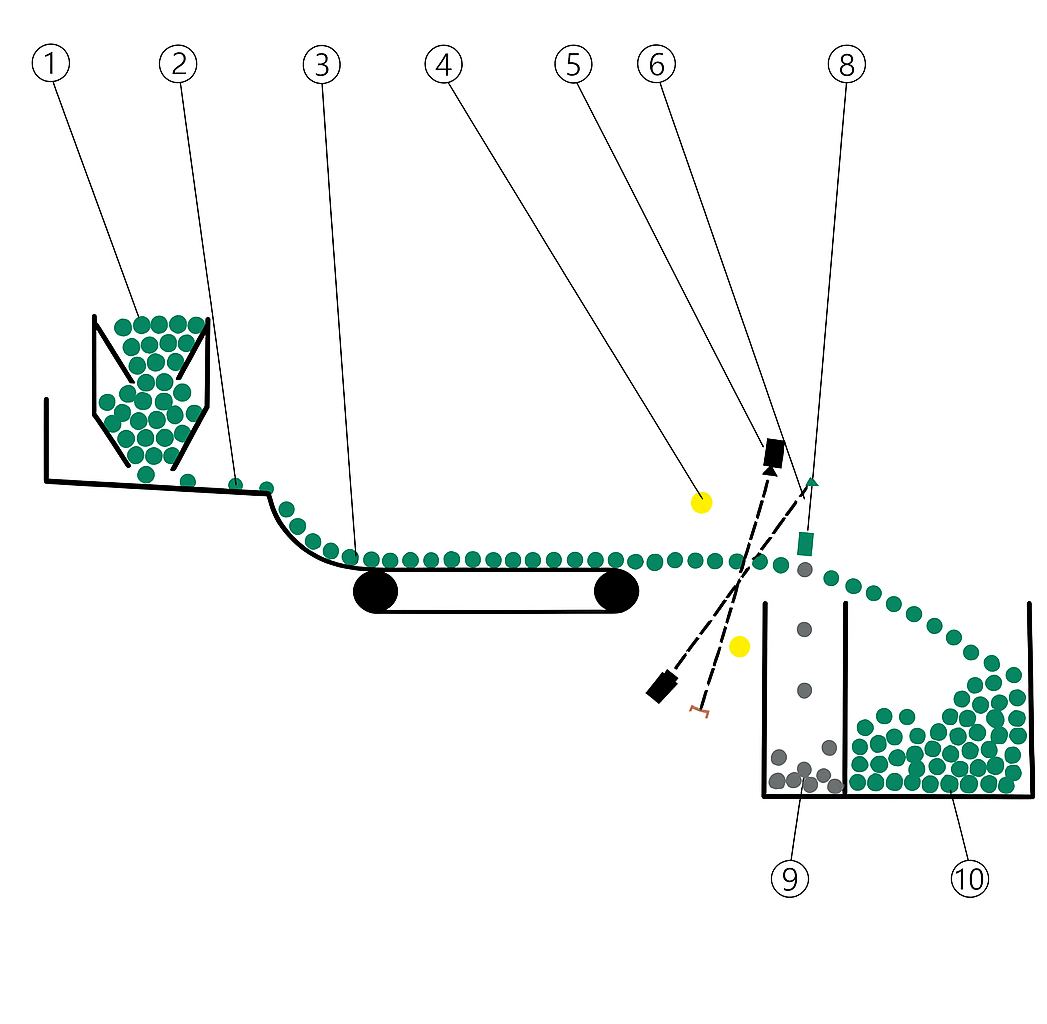

Regardless of which system you choose, the process always follows the same pattern. The only differences are in the type of feed for the material to be sorted (conveyor belt or chute), the lighting (light, UV light, infrared, X-rays), and the control system (direct or remote control).

- Feeding: The materials are poured into the machine’s container, where a vibration mechanism ensures even distribution on the conveyor belt or chute.

- Lighting: Depending on the sorting requirements, the systems use full-spectrum LED, UV, or infrared light so that the camera can detect the differences in the material.

- Identification: The technology recognizes the differences between the individual particles. This forms the basis for the next step.

- Image processing: The computer-assisted system classifies the particles according to the differences detected.

- Separation: In this phase, the ejection systems are used to reliably remove all unwanted admixtures.

- Sorting result: In the final step, good and rejected particles end up in separate containers.

Technology in detail

The graphics illustrate one of the most important differences in the feed of the material to be sorted. So-called free fallers are only suitable for certain materials. These must usually be free-flowing. Belt sorters, on the other hand, can generally be used for all materials.

Belt sorters

MEYER also offers belt sorters, which operate on a similar principle to free-fall sorters. The main difference lies in the type of material transport and the separation of the sorted material. The product is fed by a vibrating conveyor onto a conveyor belt with a specific width and speed, where it is evenly distributed across the surface of the belt and enters the detection area.

Sophisticated image processing systems (cameras in the visible light range as well as infrared, UV, and X-ray sensors) detect even the finest defects and eliminate dangerous foreign objects and particles that do not meet quality requirements.

In belt sorters, unwanted defects are removed vertically downwards, which allows for more effective removal of even the heaviest contaminants.

Belt sorters are used for materials with a sensitive structure where it is important not to damage the product. They are also suitable for very light and very heavy products that cannot be processed by free-fall sorters.

Free-fall sorter

The raw material is poured into a buffer container above the optical sorter and then dosed by vibratory conveyors and fed into the drop channel. In the drop channel, the material falls downwards due to gravity, which allows for even distribution of the particles and increases the distance between them.

The material is then analyzed in the inspection area using sophisticated sensors, cameras, and an appropriate background. After the data has been evaluated by advanced electronic control systems, the machine sends a signal to the appropriate ejection system. The Maglev® ejector hits the defective unit with a targeted air stream and efficiently removes it from the material flow. The accepted material falls directly into the designated channel for the accepted fraction.

Most machines have a re-sorting function that allows the products to be re-sorted to ensure more accurate separation and minimize material loss.

Our technology in action

The high-quality sorting performed by our sorting machines is based on the modern technology of the systems. From high-performance cameras to innovative AI and the gentle ejection mechanism, numerous components work together to guarantee consistently optimal sorting results.

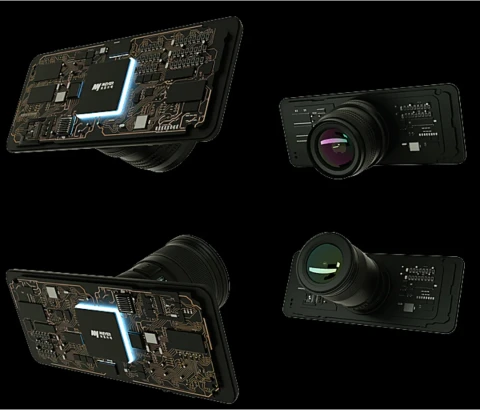

Camera

Imaging system

The advanced inspection system scans materials 50,000 times per second and captures movements in slow motion – up to 1,000 times slower than in reality. Thanks to super slow-motion technology, the actual material parameters can be accurately mapped, which significantly increases sorting efficiency. This precision forms the basis for the highest quality and reliability.

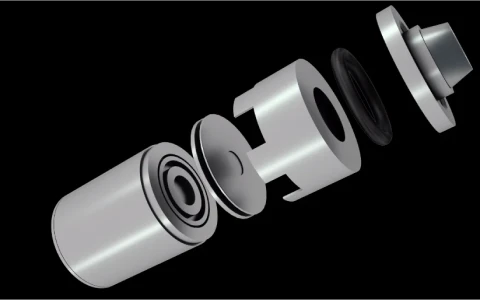

Maglev® 3.0

Ejection systems

Thanks to their contactless, floating structure, MEYER Maglev Ejectors® feature a high operating frequency of over 1,200 Hz. The unique design of the patented Maglev Ejectors gives our systems an extremely long service life. This innovative in-house development from MEYER ensures gentle sorting and makes our systems unique.

Lighting

Full-spectrum light

The LED lighting system highlights the actual color of the material and detects subtle color nuances thanks to its spectrum similar to daylight. This complete RGB spectrum analysis improves the detection of material properties and increases efficiency in identifying defects and impurities. This ensures precision, quality, and reliability.

Control

Simple user interface

The control panel of MEYER devices has been designed for maximum user-friendliness, making it easy to operate even for less experienced users. MEYER software enables remote control and real-time monitoring of machine parameters. AI-supported functions such as remote control, backups, and intelligent status checks ensure efficient machine management.

Image processing

Innovative systems

Our machines are equipped with high-resolution cameras that identify material characteristics based on color, shape, density, and material type. The minimum detection area is 0.0004 mm². The sorters feature a multispectral detection system that includes visible light, infrared, UV light, and X-rays. This enables precise removal of foreign objects.

AI-supported systems

Intelligent technology

Developed, produced, and patented by MEYER, the Maglev® 3.0 ejection systems offer fast response times and precise ejection mechanisms. The contactless (levitating) design enables a high operating frequency of over 1200 Hz, which minimizes losses thanks to the fast opening and closing times of the flaps. The result is a complete system that sets standards in precision and efficiency.